COMPETITION DISCS

TAROX racing brake discs are available for any motorsport application. The raw materials used in the manufacturing process come from specialised foundries that are ISO9000 and TÜV certified.

TAROX discs are produced from solid billet and are designed to have an exceptionally high tensile strength. The Ultimate Tensile Strength (U.T.S) for these discs is rated at 57kg per square mm, exceeding the industry standard for racing specification discs which is typically 38kg per square mm. Naturally TAROX racing discs also surpass the CEE standard U.T.S of 25 kg per square mm.

Two manufacturing processes make TAROX discs unique:

- All TAROX racing discs are subject to a residual stress relieving heat treatment to deliver superior performance in all conditions. This also enables the disc to remain stable at extreme temperatures. Heat treatment ensures TAROX discs are less prone to warping, cracking, fade and knock off, which act to reduce pad and disc life. As a result, TAROX discs provide greater braking performance and longer disc and pad life.

- After machining, the surface of each TAROX disc is manually ground to a tolerance approaching 0.015mm. This creates a perfectly level surface for the pad to contact and ensures that the discs run true.

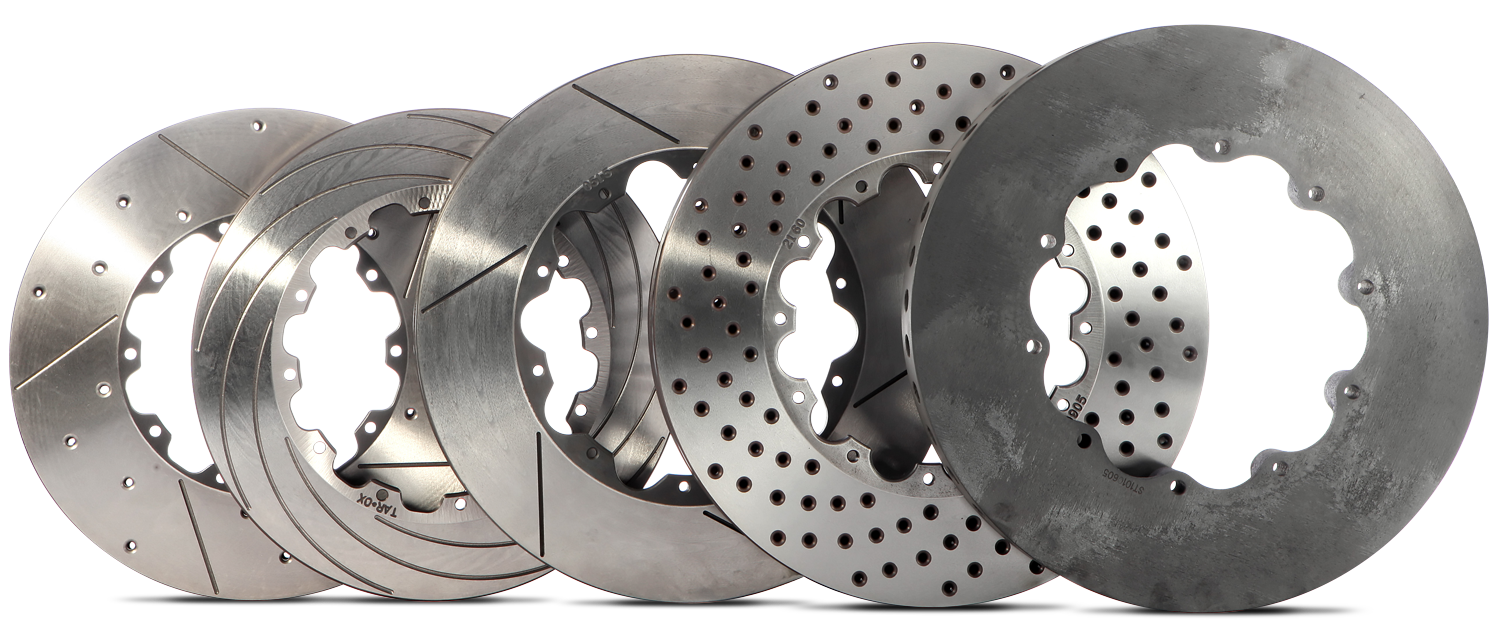

TAROX racing brake discs are available in a range of sizes from 248mm to 400mm and can be ordered with the following braking surfaces.

- Straight grooves (C83)

- Cross drilled – with countersunk drillings for fracture reduction (D95)

- Curved grooves (F2000)

- Grooves alternated with cross drilling (SJ)

- Plain braking surface (ZERO)

Racing Disc Homologation

In some racing series brake choice is restricted by the relevant technical rules: in some cases the brake surface must be perfectly plain, in others it must follow a precise pattern dictated by homologation papers. TAROX are able to develop solutions to maximise braking performance within series rules and also produce braking components to homologation specifications.

Matching discs & calipers: the “F” Factor

All discs listed in the TAROX racing catalogue are provided with a maximum pad depth (“F”). Some TAROX calipers work with a 50mm pad depth while others have a larger 60mm pad depth. When matching discs with calipers it is essential to consider this dimension to ensure the best performance. If in doubt please contact the TAROX Technical Department for advice.

Disc Mounting : Bolted vs. Floating

The TAROX racing discs list features discs with both floating and bolted arrangements. Where rules permit, floating discs are usually favoured in professional circuit racing applications. Bolted fitment is ideal where durability is preferred over outright performance; as such this method is popular for rally cars and track enthusiasts. Floating discs require cleaning to ensure correct operation while bolted discs are a more rugged option. Floating discs are preferred when stability at extreme temperatures is required. This is particularly relevant to larger disc diameters. Some TAROX kits have been prepared with floating and bolted disc options for this reason. All motorsport applications can be tailored to meet your specific requirements.

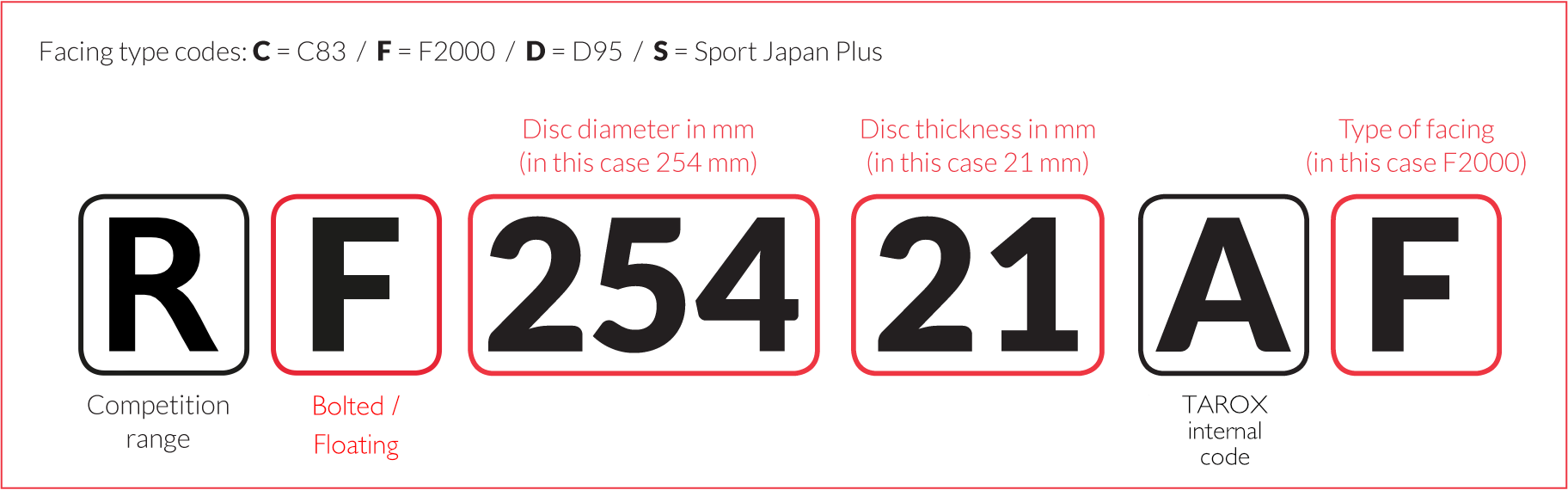

TAROX Racing Disc Codes

Each TAROX racing brake disc is identified by a unique part number.

Customised Racing Discs

TAROX list a variety of ready to order discs that cover most popular racing applications. Alternatively, TAROX can build a bespoke disc for your unique application.

Download motorsport disc template

Aluminium Alloy Bells

All TAROX alloy bells are manufactured in-house from solid billet and are made to the same exacting standards as all other TAROX components. Floating and bolted discs can be ordered complete with alloy bells or as a separate replacement rotor. Additionally, TAROX are able to offer replacement disc bells providing an accurate technical drawing is supplied. Specially ordered bells and custom parts for motorsport use can be manufactured and delivered in a matter of days and replacement disc hardware is also available separately for TAROX discs.